Working conditions in underground mines have their difficult specificity in comparison with working conditions on the surface.

Apart from the technical hazards resulting from technological processes, there are also natural hazards related to the area around the excavations (water, gas, gas and rock outbursts, gas and dust explosions, rockbursts, climatic hazards).

The deeper the deposits of raw materials, the higher the temperature of the surrounding rocks and the more difficult the working conditions.

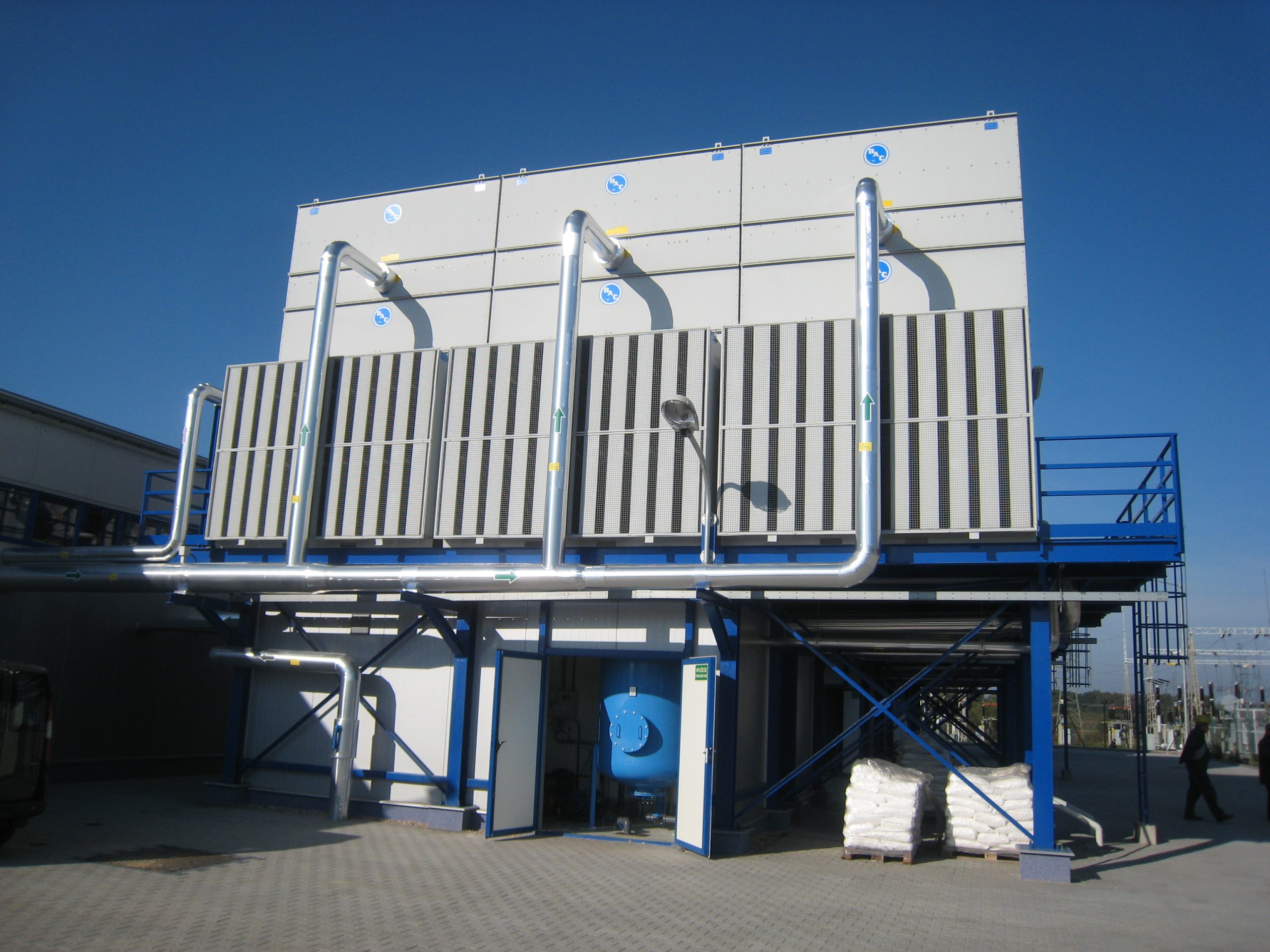

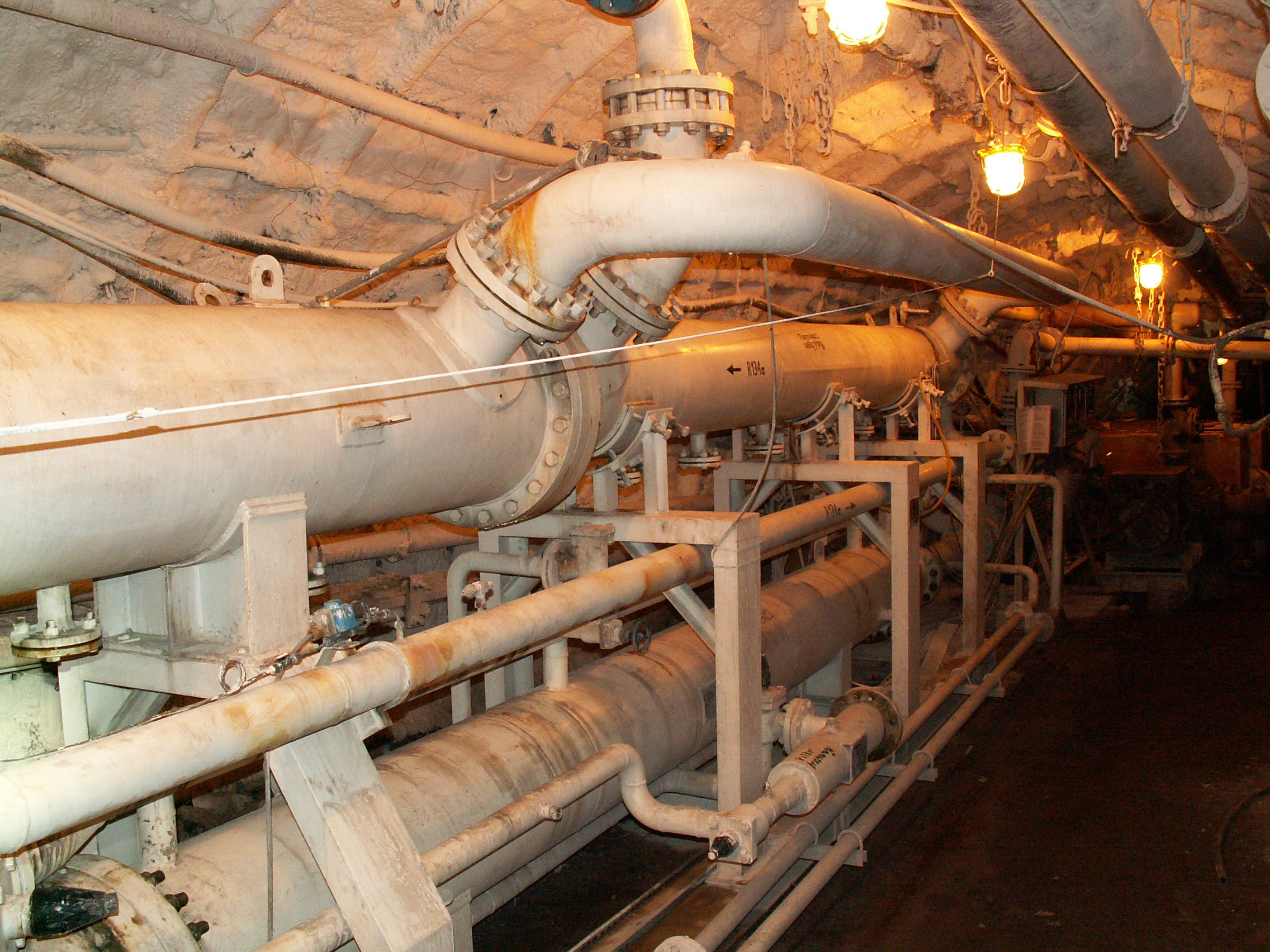

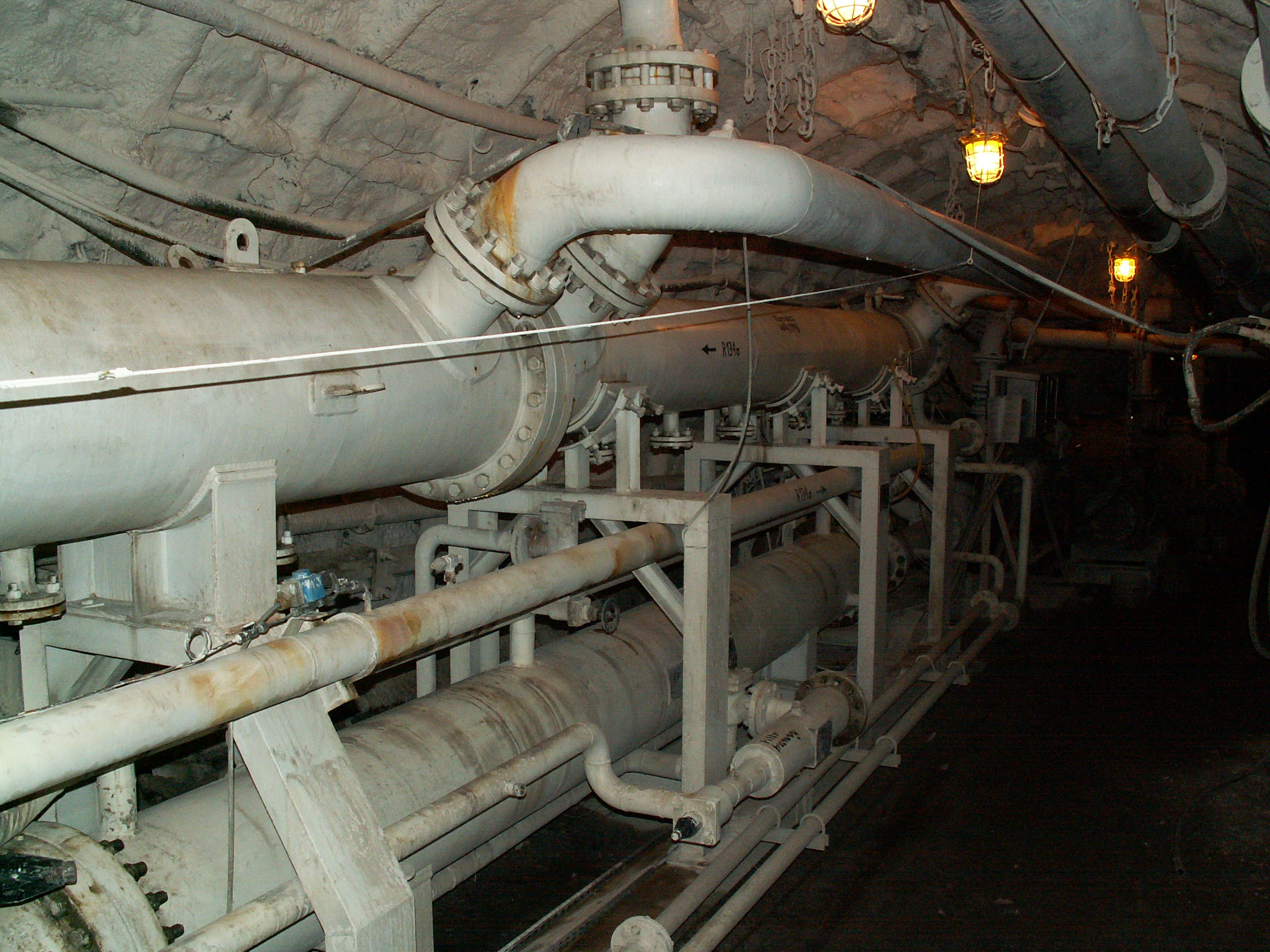

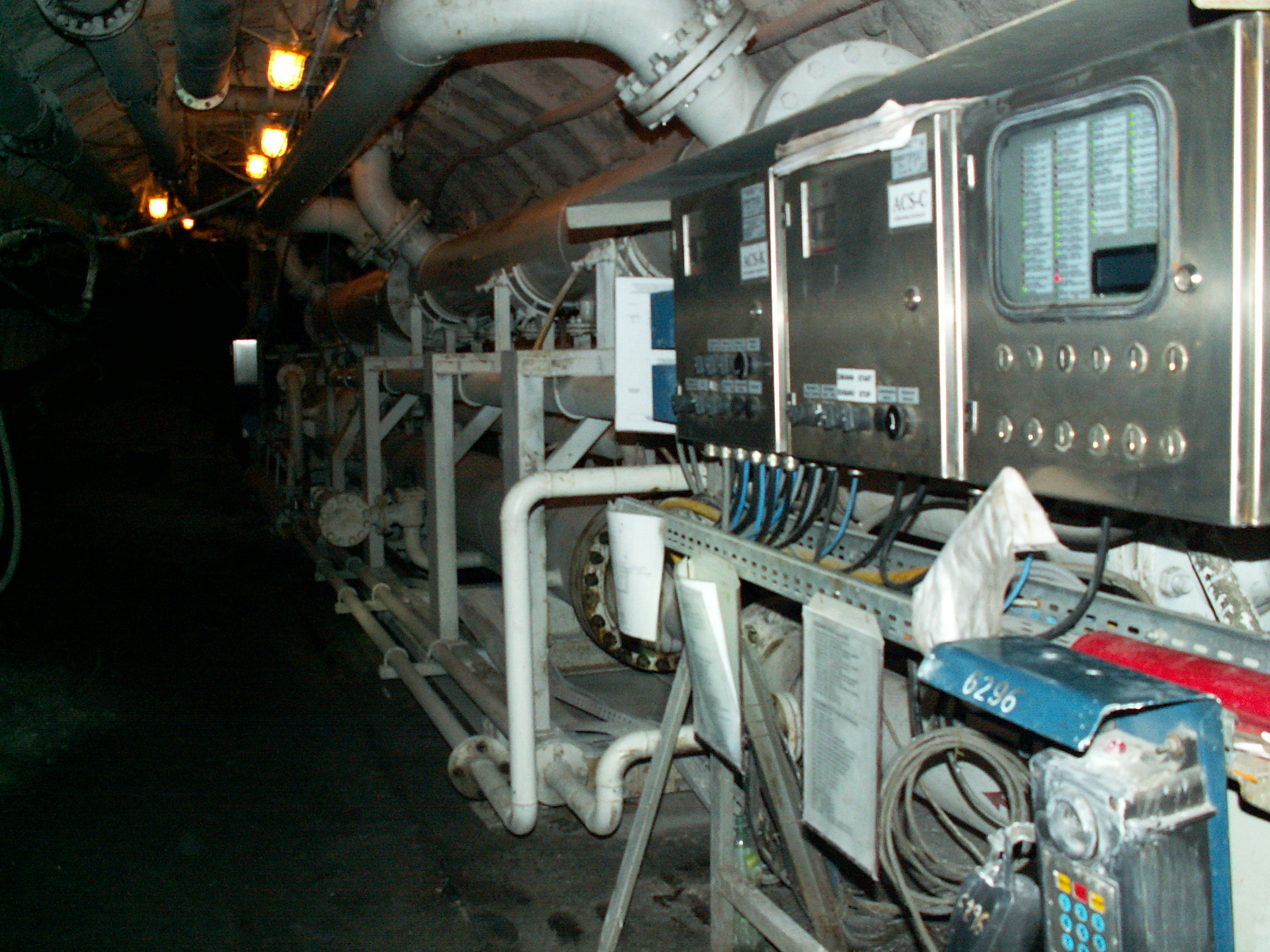

Currently exploited copper deposits in Poland from the depth of 1300 m, coal from levels 850 to 1030 and potassium salts in Belarus from 700 to 900 m require designing a ventilation and air conditioning system on the basis of local conditions and the existing and planned cross-sections of mine workings, the temperature of the surrounding rocks, the speed of air flow, the number and size of machines and people working at a given level and in a given area, as well as bearing in mind the safety and comfort of crews working underground, the size of temperatures occurring locally at a given humidity.

Polish mining law obliges the employers who employ workers underground to ensure working temperature does not exceed 28 degrees Celsius, or if it is not possible, to reduce the working time of the crew to 6 hours, and a temperature rise to 33 degrees Celsius is considered as working in emergency conditions.

Ensuring stable microclimate parameters in time by means of ventilation and air-conditioning of pits is difficult to achieve but extremely necessary for the safe and efficient work of mining crews.