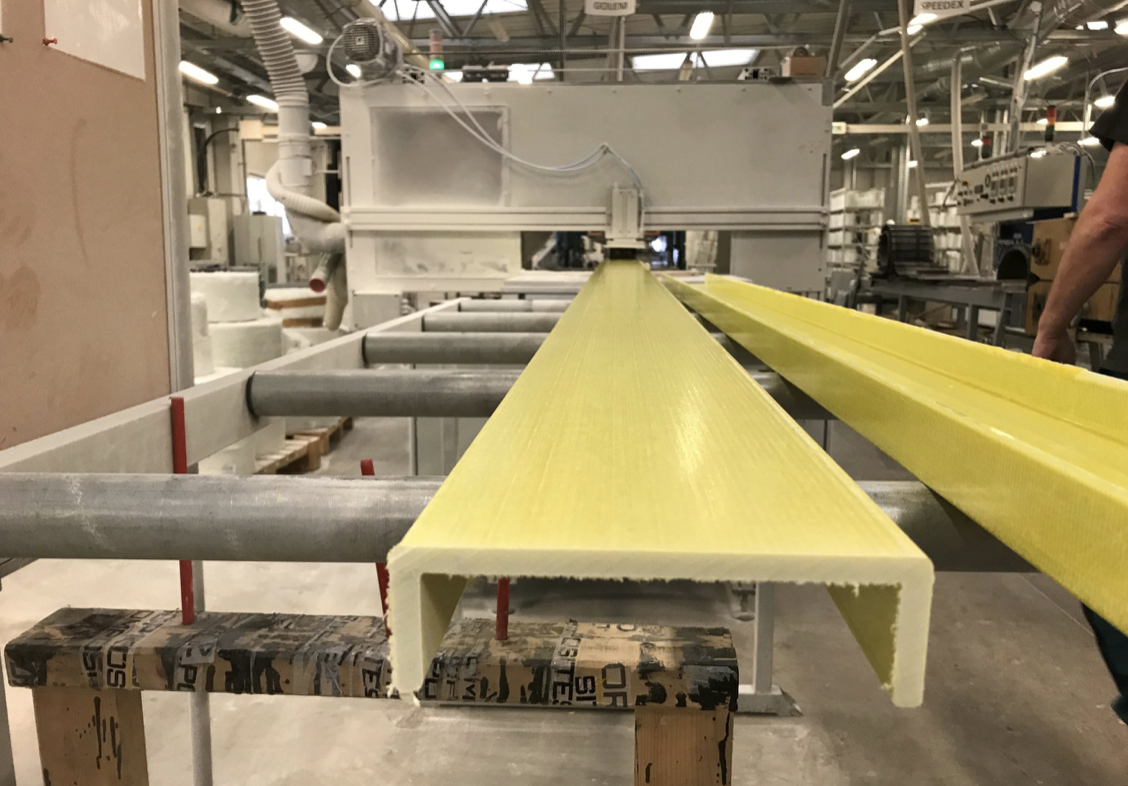

The NKG material is produced using the Pultrusion method

Pultrusion is a cntinuous method of manufacturing glass-fibre reinforced thermoset profiles. The term originates from the English “pull” and “extrusion”, and it refers to the production of profiles by pulling glass fibres soaked in resins according to the NKG formula through a system of moulds giving an appropriate shape, and then thermo-curing them.

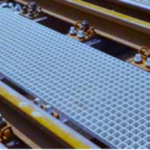

Composite profiles produced by the pultrusion method consist of polyester resins, reinforced with glass fibers with the addition of a flame retardant and antistatic agent.

Production using the pultrusion method is virtually fully automated, although the phase of developing the right mixture for the relevant technical requirements and preparing the moulds can take several months or years, hence the composition of glass roving, polyester resin, flame retardant and graphene nanotubes which meets the requirements of flame retardancy, anti-electrostaticity and non-toxicity developed by KG Consulting Krzysztof Gregorek is called NKG or New Mining Composite.